Name:Reference data for the design of Batch-type electrical furnace

View:

Reference data for the design of Batch-type electrical furnace Description:

Reference data for the design of Batch-type electrical furnace1.Heat power (kw) = weight of the object to be heated (kg) X specific heat of the object to be heated X temperature-rising speed {max. furnace temp. (℃) ÷ total heaating time (h) ÷ 860 (860kcal = 1 kw)} Suppose: unit heat-loss is 740 kcal/M2 hour

2.Heat-loss (kw) = surface area of furnace chamber (M2) X 740 ÷ 860

Suppose: the wall thickness is 10 cm and 100 ℃ is a unit constant for the furnace temperature, then the accumulation of heat on the furnace chamber is 635 kcal/M2.

3.Accumulation of heat power (kw) = {[furnace wall thickness (cm) ÷ 10cm] X [max.furnace temp. (℃) ÷ 100 ℃] X 635} X surface area of furnace chamber (M2) ÷ total heating time (hr) ÷ 860

4.The total power needed (kw) is the sum of the above three terms. Owing to the fact that the Yuhao SiC heating elements work long-term under high temp. , they gradually age and their resistance value increases and power decreases. In order to adjust it to the power needed in time, the power of transformer should be 60-100% larger than the total power needed.

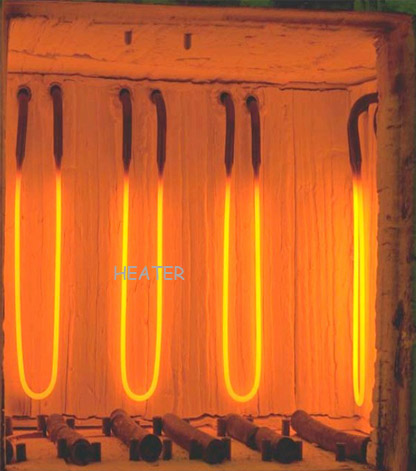

5.Select dimensions of heating elements according to furnace sizes.

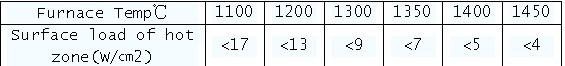

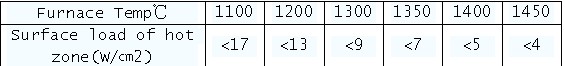

6.After determing the max. furnace temp. , caculate the power (kw) of a single element. The power(kw) = the stipulated surface load of the elements under this furnace temp. X the surface area of hot zone of the element.

- Multi-shank molybdenum disilicide heating element

- L bent MoSi2 heating elements

- Moly-D U-shape Molybdenum Disilicide Mosi2 Heating

- Special shape molybdenum disilicide heating element

- W Type Molybdenum disilicide MoSi2 heating elements

- Moly-D Molybdenum Disilicide Mosi2 Heating Element

- Booklet of MoSi2 Heating Element

- Reference data for the design of Batch-type electri