Name: Moly-D Molybdenum Disilicide Mosi2 Heating Elements

View:

Moly-D Molybdenum Disilicide Mosi2 Heating Elements Description:

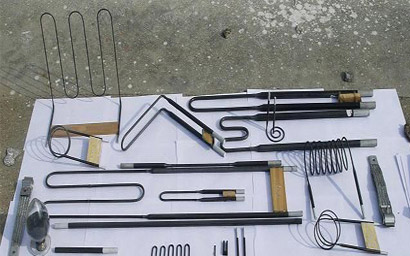

Molybdenum disilicide (MoSi2) heating element is a resistance generate-heating component made from MoSi2 or the basic material. It is used in high temperature under the oxidizing atmosphere.So this kind of element has unique effect for resisting oxidization in the high temperature. It is used to the highest temperature up to 1800C during oxidizing atmosphere. According to your request, our company can produce the products of Pole, "U", "W" and "U"-right angle shapes, etc. MoSi2 heating element can usually make use of furnace temperature from 1300C to 1800C. It is extensively used in the industries of metallurgy, glass, ceramic refractory, crystal electronic device, industrial furnace manufacture, etc.. It is an essential ideal element when the products are sintering in the high temperature.

Why choose our Mosi2 heating elements?

|

Applications |

Laboratory furnace |

Sintering furnace |

Glass melting furnace |

Heat treatment |

|

Industrial furnace |

Glass melting furnace |

Testing equipment |

Metal sintering |

|

|

High Productivity |

MOSi2 can be used for high surface loadings |

|||

|

Arranged in groups to give wall loadings in excess of 100kW/m² |

||||

|

Energy Saving |

||||

|

MOSi2 enable user to startup only when needed |

||||

|

Flexibility |

Wide range of temperature range 500℃ to 1800℃. |

|||

|

Able to expose in many protective atmosphere used in practic |

||||

|

Reliable Production& Low Maintenance |

MOSi2 can withstand oxidation at very high temperature |

|||

|

Unmatched durability |

||||

|

MOSi2 does not age, thus enable connection between existing and new elements |

||||

Advantages

- Available in a variety of shapes and sizes

- Highest operating temperatures and watt loadings of the elements under consideration

- Stable resistance; new and old elements can be connected in series

- Fast, thermal cycling possible without element degradation

- Relatively easy to change while the furnace is hot

- Longest inherent life of all electric heating elements

Unique Properties

- Moly-D elements may be used up to a surface temperature of 1800ºC (3270°F) in oxidizing atmospheres.

- Long service life and ease of replacement contribute to high furnace utilization and low maintenance costs.

- New and old elements can be used together and in series.

- Can dissipate high power loading.

- Can be used continuously or intermittently.

- Provide rapid furnace temperature ramping.

Type MD-31

Maximum Element Temperature - 1700°C (3090°F) General Applications -- Most types of industrial furnaces for heat treating, forging, sintering, glass melting and refining, and for use in radiant tubes.

Type MD-33

Maximum Element Temperature - 1800°C (3270°F) General Applications - Laboratory furnaces, testing equipment, and high temperature sintering production furnaces.

Standard sizes:

M1700 type ( MD-31) (d/c): dia3/6, dia4/9, dia6/12, dia9/18, dia12/24 M1800 type(MD-33) (d/c): dia3/6, dia4/9, dia6/12, dia9/18, dia12/24

Order sample:

d=6mm, c=12mm, Le=200mm, Lu=180mm, a=30mm

Please specify as: dia6/12x200x180x30mm (dia d/cxLexLuxa mm)

d = the diameter of hot zone

c = the diameter of cold zone

Le = the length of hot zone

Lu = the length of cold zone

Examples of typical MoSi2 element configurations.

|

3/6mm |

de=Ф3mm |

du=Ф6mm |

D=25-30mm |

|

6/12mm |

de=Ф6mm |

du=Ф12mm |

D=30-50mm |

|

7/14mm |

de=Ф7mm |

du=Ф14mm |

D=30-50mm |

|

9/18mm |

de=Ф9mm |

du=Ф18mm |

D=35-60mm |

|

12/24mm |

de=Ф12mm |

du=Ф24mm |

D=60-100mm |

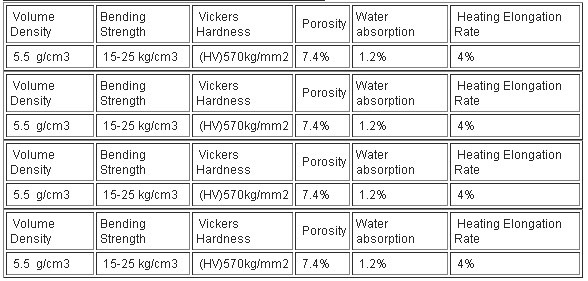

Physical Characteristics

MoSi2 heating element is used in the high temperature under oxidizing atmosphere. It will form the SiO2 film which can keep the element from being melted. During the oxidizing process, the SiO2 protecting film is formed again when the element continues to be used. The MoSi2 heating element must not be used in the temperature between 400C and 700C for a long time, otherwise the element will be cremated under the strong oxidizing function in the low temperature.

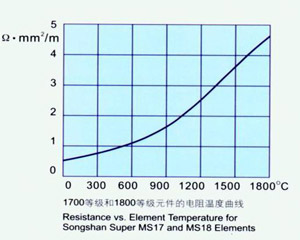

Electric Characteristics

The resistivity of element rapidly rises as the temperature rises, under normal operating conditions, generally the element resistance doesn't change with the service time changing. So the old and new elements can be mixed used.

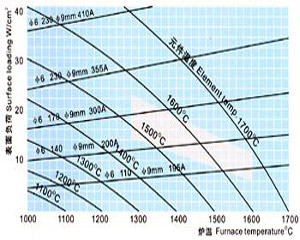

2)Surface Load

According to the structure, the temperature and atmosphere in the correct choice of components surface load is the key element to the highest life, based on the thermal radiation components uncrossed circumstance temperature, temperature and surface load components, the shaded part for common surface load - - - - - the temperature range.

Installation and Advice

1). Vertically Hanging

Under normal temperature, MoSi2 element is very brittleness, while under high temperature it is plasticity. So, the better way for installation if the U Shape element is to hang it vertically, to the furnace top through the support clamping chuck H. The aim of such way is to avoid putting the mechanical stress directly to the element heat-generating end, or the element will easily be broken.

2). Support Clamp

Support clamp are applied to &9/18 and &6/12 two kinds of elements respectively. The support clamp supports the whole weight of the element and the position of the element is also determined by it .therefore ,it must be installed carefully to assure that the element it vertically hung. In order to prevent the element from being over heated locally, the taper part of the element lower end must put into the furnace chamber.

3). wire clip

The wire connection clamp connecting MoSi2 element is made of aluminum woven wire or multilayer aluninum foil. The steel plate outside it only acts as a clamp and isn't used for electric conduction. For&6/12 element, single rowing wire is used ,and for &9/18element,double-rowing wire is used ,the end of the lead wire should be a little larger than the linear distance between the element and bus.

The brittleness of MoSi2 heating element is relative more under the usual temperature; it also has plasticity under the high temperature. So you had better hang and erect vertically the "U"-shape element. If you need to erect it horizontally, please choose a support of high-temperature insulating materials. The cone-part of the element must extend inside the furnace. At first the fixture of MoSi2 power connector can’t be screwed too tightly. When temperature of the element is going up, please twist it tightly again, so the element is not easily broken.

(Our suggestion: please choose the specialize power connector provided by our company)

The furnace top must be a good function of heat-preservation. In general, the temperature of furnace top can’t be over 300C. The voltage should be low 0.1 between the power connector and the element. In order to avoid radiating heat to pass the connector, the distance is not less than 50mm between the low end of connector and the upside of the ceramic brick. The Dia.6 /12 element can't be used of 170A for a long time. The Dia.9 element can't be used of 300A for a long time.

Made to Industry Standards

Moly-D heating elements are manufactured to industry established resistance values. The same spacing, power ratings and voltages, used with other molybdenum disilicide elements can be used.

Delivery

Most sizes and types can be shipped 2 to 3 weeks after receipt of an order. Emergency shipments for 3/6 and 6/12 can usually be made in 2 to 3 days.

Technical Assistance

We can assist you in choosing the most suitable element material and element type for your application. We also offer free engineering service for a new furnace design or a conversion from gas or oil fired to electric heating.

Customers of Torch MoSi2 elements enjoy two key added benefits – first, unparalleled price and second, experienced engineering support. Anyone can sell MoSi2, but knowing how to design the system is where Torch excels. MoSi2 systems must be engineered for customer to get the best performance and optimum service life. Torch engineers can assist in:

analyzing the relationship between the furnace temperature, element temperature and the element surface load

selecting the element surface load according to the furnace construction, atmosphere and operating temperature

choosing the most suitable element size and style for your application

- Booklet of MoSi2 Heating Element

- Moly-D U-shape Molybdenum Disilicide Mosi2 Heating

- L bent MoSi2 heating elements

- Multi-shank molybdenum disilicide heating element

- Reference data for the design of Batch-type electri

- W Type Molybdenum disilicide MoSi2 heating elements

- Moly-D Molybdenum Disilicide Mosi2 Heating Element

- Special shape molybdenum disilicide heating element