Name:The booklet of silicon carbide heating element

View:

The booklet of silicon carbide heating element Description:

This bulletin provides useful information on the handing, storage, installation, operation, and maintenance of Torch Furnace SiC heating elements.The booklet of silicon carbide heating element

This bulletin will help you achieve maximum performance and service from your Torch Furnace SiC heating elements, thereby reducing your operating costs.

The information, recommendations, and opinions set forth herein are offered solely for your consideration, inquiry, and verification, and are not, in part of total, to be construed as constituting a warranty or representation for which we assume legal responsibility. Nothing contained herein is to be interpreted as authorization to practice a patented invention without a license.

Handling

Torch Furnace silicon carbide heating elements have high compressive strength. They are relatively low in tensile strength, however, and are sensitive to mechanical shock.

To avoid breakage, handle elements carefully at all times—even when the elements are still packed in their shipping cartons. Remember, an element can be broken merely by dropping or bumping the carton.

Never pick up an element by one end—handle with both ends.

Unpacking and Inspecting

Shipments should be unpacked and inspected as soon as received. Packaging is designed to protect elements in transit. Dropping or bumping a carton may break the element inside without damaging the exterior of the carton.

Here’s how to unpack and inspect:

Lay shipping carton on a flat surface.

Cut tapes and carefully open top of the shipping carton—not the ends.

Remove individual boxes with both hands. Don’t pry them out.

Place element box on a flat surface, cut the tapes, and carefully open the cover.

Turn box on its side and gently ease out the wrapped element.

Carefully roll the element out of its packing.

Don’t rip the wrapping off the element.

Don’t open the end of the carton and try to pull the element out.

Don’t hold the element by one hand and pull or lift it out of its box.

Never inspect an element by merely pressing on the wrapped element, or by lifting one end up off the fiat surface.

Storage

To reduce the possibility of accidental breakage, Torch Furnace SiC heating elements should be stored horizontally and fully supported on a flat surface in the original wrappings and boxes.

After inspecting, roll elements back into the packing, as received, and place them back in their boxes.

Store elements horizontally in a special warm, dry storage area. Be sure the elements will not be accidentally bumped and broken. Do not stand them on end.

Place boxes in stock, on by one, on a firm, flat shelf that is long enough to support the entire length of the boxes. Avoid excessive stacking.

Grouping

Torch Furnace SIC heating elements may be connected in parallel, series, or a combination of the two, called series-parallel connection. A parallel connection is usally best; however, two in series is also commonly used. It is recommended that no more than three or four elements ever be connected in one seried group. A total of six elements can be connected in a series-parallel combination by having three parallel groups of two in series.

Installation

Remember, element breakage can occur during installation, if proper care is not used.

Here’s how to install Torch Furnace SiC heating elements:

Before installing, be sure the correct Torch Furnace SiC heating element size is being installed. Next, check the straightness of terminal holes through walls, and the alignment of holes in opposite walls by passing a rod of suitable diameter through the terminal holes in opposite walls. Some clearance must exist, because there may be a slight shift in brickwork during heatup. If too tight or not straight, ream the hole out and align before installing elements.

In horizontal installations, move elements straight through the furnace chamber and walls. Avoid hitting the opposite wall. Don't’ force elements into terminal holes or put any unnecessary stress on them.

Center the element in the chamber so no portion of the heating section is in the brickwork. One approach is to slip a thin sheet of ceramic fiber paper under three or four inches of the terminal end of the element. The paper will prevent the element from sticking to the brickwork should any metallic or glassy vapor condense in the terminal holes.

Lightly tuck the open space around the element with bulk fiber. The fiber should only go back into the terminal hole one-half to one inch. It will cut down on heat loss through the terminal hole.

If the element inside diameter is not plugged, gently pack inside diameter with insulation. Form a one-inch-thick plug from end of element to prevent radiation losses.

For vertical installations of Torch Furnace SiC heating elements, center the heating section in the chamber and lightly tuck the open space around the element with ceramic fiber. The element should be supported at the lower terminal only to avoid breakage. Never suspend an element from the upper terminal or subject it to tensile stress in any way.

When installing Torch Furnace double spiral type heating elements horizontally, position the element so the slot in the terminal end does not lie against the brickwork or terminal tube. It should be at right angles to the vertical axis of the terminal hole or the terminal tube. This is important to prevent short-circuiting from materials depositing in the element slot. Insulating terminal tubes should be used when installing double spiral type elements and, as necessary, should be replaced each time a new element is installed if they are cracked or any deterioration is noted.

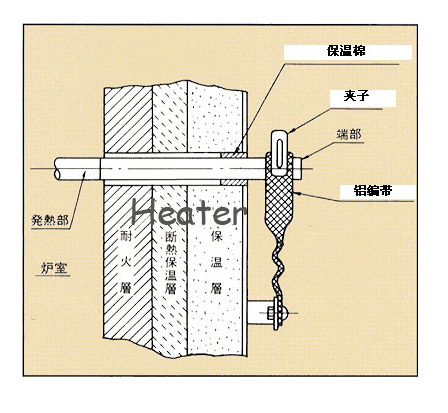

Connections

Care must be used when placing the terminal straps and clamps on elements to help prevent breakage. Here’s how to make the electrical connections:

An aluminum strap of the proper amp rating should be wrapped around the terminal end of Torch Furnace SiC heating elements and held in place by either “H” or “C” type alloy clamps.

Type “H” clamps, with wings, are used when there is enough space available for the clamp to be fitted on the element without short-circuiting the element.

When the “C” clamp is required, be sure to use the expansion tool when fitting it on the element in order to avoid mechanical breakage.

Be sure enough stack is left in the straps to allow for element expansion.

Be sure sufficient clearance is left between the clamps and the furnace shell to prevent electrical contact between the two when the furnace is up to temperature.

Don’t hit the elements when making the electrical connections or replacing the terminal guards.

Operation

Startup-During startup, apply minimum voltage (lowest transformer tap setting) to the elements. This is usually 70%-80% of the nominal full-load voltage. Any silicon carbide element may be weakened or fractured by heat shock if excessive voltage is applied in bringing the furnace up to temperature too rapidly. Increase voltage as required to obtain heat up schedule, but do not exceed full-load voltage.

Operation-During operation, use the lowest voltage that will maintain the desired furnace temperature. This allows the surface temperature of the elements to be as low as possible in relation to the furnace temperature.

Never exceed the recommended watt loadings or temperatures specified in the Technical Data. Generally, the lower the watt loading on the elements, the better their service life.

Dry out the furnace thoroughly before starting up. Moisture causes elements to oxidize, thus reducing service life. Elements should never be operated in steam.

Atmospheres .

Torch Furnace SiC heating elements can be operated at up to 1450℃ in air. Some atmospheres, at certain temperatures, shorten the element’s life. The dew point of the atmosphere and the watt loading on the element are also factors that combine to affect element life. Torch Furnace SiC heating elements can be operated at up to 1290℃ in hydrogen and disassociated ammonia atmospheres. Endothermic gas can be used, up to a CO content of 18%, with no effect on the elements. Methane and hydrocarbon vapors reduce element life. Torch Furnace SiC heating element will tend to pick up carbon, which is deposited throughout their structures. This proceeds slowly, and the resistance drop can be noted by a gradual increase in amperage. The carbon has no detrimental effect on the element; however, it does short-circuit sections of the element, thus increasing the electrical load on the remaining section and reducing the life. The carbon condition can be burned out by shutting off the atmosphere and introducing air into the furnace chamber at periodic intervals.

If possible, keep excessive moisture, methane, and hydrocarbon vapors out of the high-temperature zone of the furnace, where the elements are located.

Be sure the combination of element watt loading, temperature, and atmosphere is suitable at all times. Do not exceed limits recommended.

In-Service Inspection

All elements in a furnace must be operative. If not, the voltage has to be increased to maintain the temperature. The watt loading on the other elements is increased, thus shortening their life. This is especially important with elements in series, because if one becomes inoperative the others in the series connection will also be inoperative. Check the elements every week or so. Set the temperature controller to the manual setting, so constant power is being applied to the elements. The current can be checked by hooking a clamp-on type ammeter around the terminal strap leading to the element. When elements are in parallel, the voltage may be taken from the voltage tap setting or from a measurement across one element. If elements are connected in series, the voltage across each must be measured. The resistance is equal to the volts, divided by the amperes. Records can be kept of the current readings and resistance values. Inoperative elements, or groups found to be out of balance, should be replaced. Remember to return the temperature controller to the automatic setting after taking the above readings.

Resistance measurements of a Torch Furnace SiC heating element should always be taken hot-usually at furnace operating temperature. Measurements made on cold elements do not give accurate resistance values due to the element being a semiconductor.

Periodically check to determine if the elements are free in their terminal holes. Also, check the thermocouple, pyrometer, and other control equipment.

Good operating and maintenance techniques pay off. They affect the amount of service that can be obtained from silicon carbide heating elements.

Caution: All in-service inspections involving electrical measurements shall only be done by authorized, knowledgeable personnel following safe operating procedures. Whenever possible, meter connections shall be made with the power “locked out and tagged”.

Replacement

Important factors-Always operate a furnace with a full complement of heating elements.

Be sure the spare elements are of the correct physical and electrical specifications for the particular furnace or kiln.

Order elements in matched sets based on the number of elements in series or within a specific control group.

Avoid mixing new elements with old ones. Keep at least one spare set of Torch Furnace SiC heating elements in stock. Anticipate your needs in advance. Don’t wait until the furnace is shut down to order replacement elements.

Reduce the voltage to the lowest value when replacements are made.

Be sure to turn off and lock out power before changing elements.

Install the new or replacement elements. And adjust the voltage for the minimum value for the required load.

Never overload elements by applying an excessive voltage to get the furnace up to operating temperature in a hurry.

If an element is accidentally broken early in its life, it may be replaced with a new one. A better match will be obtained if a new element with low amperage rating (one towards the high end of the resistance tolerance) is selected. Generally, a replacement may be made with a new element when the average resistance of the elements in the group has not increased in resistance more than about 10%of the nominal resistance. If the broken element is in a series connection, it is usually necessary to replace all the elements connected in the series circuit. Elements in series must be matched closely.

If an element has broken after the elements in the group have increase more than 10% in resistance, the entire group of elements should be replaced. If a used element of similar resistance (one which has increased in resistance approximately the same amount as the group) is available, then it could be used as a suitable replacement.

Occasionally, it is necessary to remove and replace some serviceable elements remaining in a group where a failure has occurred. Mark the resistance, the current drawn, and the voltage applied on the box in which the used elements are stored. Later, such elements may be matched into sets and returned to service.

Key Factors Affecting Element Life

Operating temperature.

Watt loading applied to element.

Composition of atmosphere surrounding the element.

Type of operation-continuous or intermittent.

Operating and maintenance techniques

Words of Wisdom

Handle Torch Furnace SiC heating elements carefully at all times.

Inspect Torch Furnace SiC heating elements immediately upon receipt.

Take a picture of the broken heating element after inspection.

Store Torch Furnace SiC heating elements in a dry and protected storage area where they cannot be accidentally bumped and broken.

All elements in the furnace must be operative.

Replace any elements that have failed and be sure that groups of elements are balanced.

Don’t forget to turn off and lock out the power before replacing elements.

Don’t mix new elements with old elements.

Install elements carefully and be sure they are free to expand and contract at all times-when the furnace is hot, as well as when it is cold.

Be sure the heating section is centered in the chamber and not back in the wall.

On startup, with new elements, use minimum voltage-usually 70%-80%of full-load voltage. Bring elements up to temperature slowly on lower voltage taps, and adjust the voltage upward as the furnace heats up.

Operate elements on the lowest voltage that will maintain the desired furnace temperature.

Don’t exceed the recommended watt loadings or temperatures shown in Technical Data.

Use as low a watt loading as possible to obtain more favorable performance.

Don’t subject the elements to unnecessary thermal or mechanical shock.

Don’t blow air into the chamber for rapid cooling.

Never try to measure the resistance of a cold element-it must be hot to obtain a reliable value.

Maintain matched resistance circuits at all times. Establish a good maintenance program with periodic inspection of Torch Furnace SiC heating elements and control equipment. Handle elements carefully at all times. Keep at least one spare set of Torch Furnace SiC heating elements in stock at all times.

Electrical checks shall be carried out only by authorized, knowledgeable personnel.

Thing to Check to Avoid Trouble or to Solve a Problem

Are the correct-size Torch Furnace SiC heating elements being used?

Are there any inoperative elements in the furnace?

Are the terminal holes straight and in alignment so the element doesn’t blind?

Are the elements free to move in the furnace?

Are the heating sections centered in the chamber and not back in the wall?

Are elements resting flat in the terminal holes?

Are any elements sticking in the terminal holes from foreign material condensing in the holes?

Are new elements being operated in series with old ones?

Are elements overheating?

Are the elements in a control group balanced-that is, drawing similar current?

Are the transformer taps set correctly to permit all elements to operate at recommended watt loadings?

Are any terminal straps too snug, thus putting a stress on the elements?

Are any terminal clamps too close to the furnace wall, thus preventing expansion and contraction?

Are all the electrical connections tight, so power is being applied to the elements?

Is the temperature-control equipment working correctly?

Has the composition of the material being heated or the load been changed in any way?

Has the heating cycle been changed?

Are the elements being attacked by any chemicals burned out of the charge?

Has the composition of the atmosphere been changed?

Has the moisture involved increased and become detrimental?

Is carbon being deposited on the elements or on the brickwork of the chamber?

Is anything dripping onto the elements?

Is the material being heated too close to the elements?

Are elements being hit when the furnace is being loaded or unloaded?

Are elements being subjected to vibration or floor shocks?

Have any new operators or maintenance personnel read this booklet?

Are elements being handled properly and carefully at all times?

- Introduction of Torch Furnace Sic Heating Element

- Type RA(U-1) Silicon Carbide Heating Elements

- ED (RR) rod type silicon carbide heating elements

- SG (single spiral)type Silicon carbide heating elem

- DB(GC) SiC heating elements

- U Type Silicon Carbide heating Element

- Silca Type W - Three Phase(Multi-leg) Silicon Carbi

- The booklet of silicon carbide heating element